Episode 8 – Engineered Wood Floors Have a Comfort Zone Too.

Hardwood flooring is manufactured in many widths and cuts to provide a multitude of design opportunities per species of hardwood. One design element we are seeing become more popular is wood flooring that is 6” to 10” wide and is chosen for the beauty and presence it brings to a room.

In dryer parts of the country or in a market that can experience a dry heating season, a solid flooring in 6” to 10” width would make just about any installer cringe due to the potential movement that floor could go through. To minimize this movement, manufacturers have put their wider plank products onto an engineered platform and have sold them as a more stable option to its solid counterpart. In higher moisture conditions, that engineered flooring will perform better during seasonal changes by not adversely reacting to a higher moisture were a solid may show signs of cupping quickly.

For years, the industry has used an image like the one above, stating the use of solid flooring should only be used on or above grade. Whereas an engineered flooring can be used on all three grades. This is due to the engineered flooring having more dimensional stability to handle the potential of a slightly higher moisture level in a below grade situation.

To the left are the most common types of engineered flooring platforms. If correct living conditions are not maintained in the home, either too high or too low of humidity, the flooring can be stressed and you may start to see unsightly gaps, squeaks and pops as fasteners start to work free from the subfloor and in worst case scenarios, the plies of the engineered flooring starting to tear apart.

While an engineered floor may be able to withstand a slightly higher amount of moisture before showing signs of wood distortion (i.e., cupping or warping), in a dry environment the structure of an engineered plank will tend to hold together so well that by the time you start to see the signs, it may be too late.

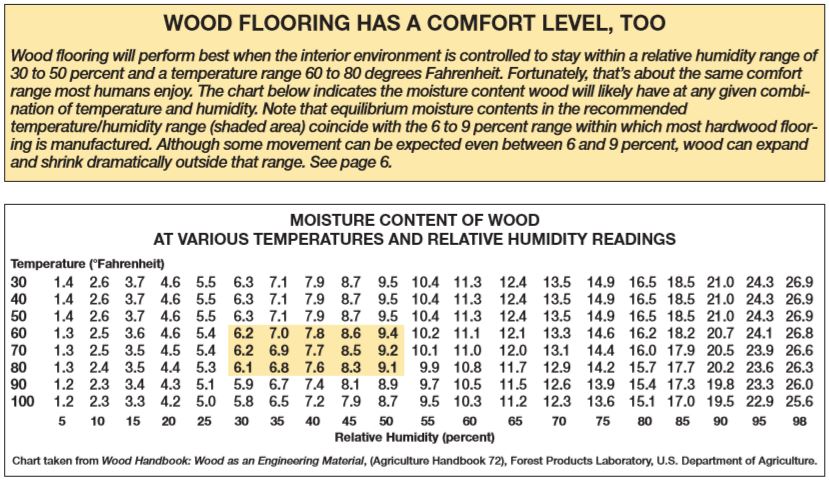

Some of the platforms pictured above may handle a wider variance in humidity levels and the manufacturers who utilize the different platforms will have a range that their product performs best in. I have seen in most manufacturer’s guidelines that they require to maintain 35% to 55% humidity with a range of 60° – 80° temperature.

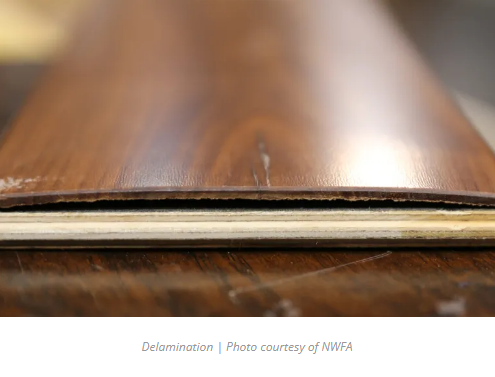

When an engineered plank is exposed to an extended period of dry conditions, the layers of the substrates are stressed, potentially causing irreparable damage to that plank. If held in this situation long enough, the layers can start to peel apart and may appear as ‘Dry Cupping’ as pictured below on the left. Internally, the plies are ripping apart and if examined once the plank has been removed, you will see the ‘Wood Shear’ where the plies have torn like the picture on the right.

This issue is commonly misdiagnosed as delamination. The NWFA defines delamination as “The separation of two layers/plies within a piece of engineered flooring due to the lack of an adhesive bond is typically identified as a clean separation at the glue-line.” This would be a complete, clean separation between the plies and not show torn sections as shown in the image above. A wood floor that is showing signs of dry cupping or wood shear will usually have moisture content readings that indicate that the flooring has been exposed to very low humidity conditions.

Dry Cupping and Wood Shear is not considered a manufacturer defect and is not covered by the warranty since the environmental conditions of the home were not maintained according to the manufacturer’s Maintenance and Warranty Guidelines. Here is the phrasing one engineered manufacturer has on their website regarding wood flooring and its reaction to environmental conditions:

“Wood is a product of nature. As a natural material, it will expand and contract as it gains and loses moisture. Some gaps between the boards during low-humidity seasons are normal and not considered a defect. Maintaining optimum humidity levels of 35% to 55% will minimize these occurrences. Allowing relative humidity levels to fall below 35% can result in structural damage to the floor such as large gaps, splits in the surface, distortion of the boards and structural failure”.

Maintaining these correct environmental conditions will keep these issues from happening. Start by adding a thermo-hygrometer to be able to monitor the humidity. If your current HVAC system cannot maintain these conditions, additional moisture control systems may be needed to help keep the temperature and humidity of the home within the manufacturer’s suggested environmental conditions to maintain their warranty.

Additional information can be acquired from the manufacturer’s technical department of the products used on your floor. The National Wood Floor Association (NWFA) can be an additional resource. They can be reached at 800-422-4556 or online at www.woodfloors.org.

This article was also featured in the Hardwood Floors Magazine. Click here to see that article.