Episode 4 – Nailer Recommendation for Engineered Flooring.

Within many flooring companies, it has become standard to install laminated flooring with a 20 gauge flooring stapler or ‘floor runner’. While engineered flooring may sometimes be confused with being “laminated”, they are different materials and cannot be installed with the same fastener.

Most laminated floors are thinner (1/4” – 1/2”) and constructed of a composite material that may require a thin gauge staple so that the fastener does not telegraph into the face of the material. Engineered flooring is usually constructed of plies of plywood or sometimes fillets and glued together in opposing layers. The final material thickness can range from 3/8” to 3/4”. With this additional thickness, a 20 gauge flooring stapler that may be sufficient for a laminate floor will not have the holding power to properly fasten an engineered floor.

The main reason this is not a suitable fastener is because a 20 gauge ‘floor runner’ can only accept a staple length of 1”. Inserting a 1” staple at the industry standard of 45 degrees into a 9/16” flooring, you are only penetrating into the subfloor about a 1/16 of an inch. This is not nearly enough holding power to hold down hardwood flooring and will come loose from the subfloor when that floor goes through any seasonal changes.

A common recommended fastener for engineered flooring is an 18 or 20 gauge staple or cleat in a nailer that will accept a fastener length up to 1-1/2”. There are many manufactures that make a gun that will accept these fasteners. Two nailers we have seen to be very versatile are the Powernail 50P and 50F that are pictured below.

The 50P and 50F are 18 gauge cleat nailers that have many options, but one particular option that makes these guns versatile is the option to adjust the foot to the flooring thickness you are working with. The 50P is mallet actuated and the 50F a trigger pull, both will fasten flooring from 3/8” to 3/4”, utilizing a cleat 1” to 1-3/4” in length, allowing for the correct fastener penetration into the subfloor.

On the opposite side of this concern, using a standard hardwood flooring fastener (15.5 gauge staple or 16 gauge cleat) on engineered flooring may provide the correct subfloor penetration, but you will risk the fastener telegraphing through the surface of flooring.

As always, check with the installation guidelines of the material you are working with as most flooring manufactures have suggested guns to install their flooring. You may find that most recommend the 50P or 50F.

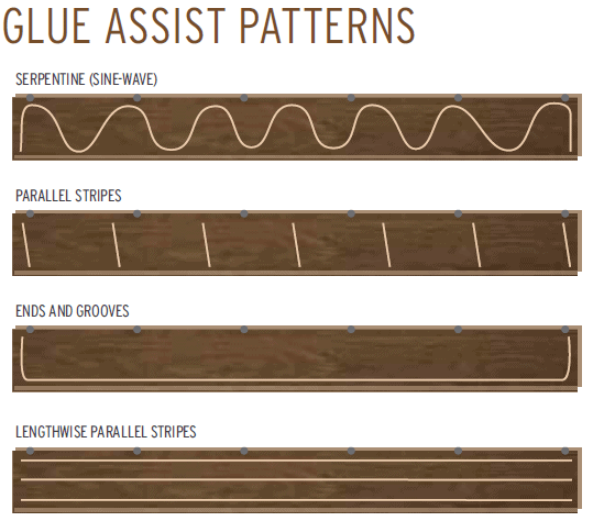

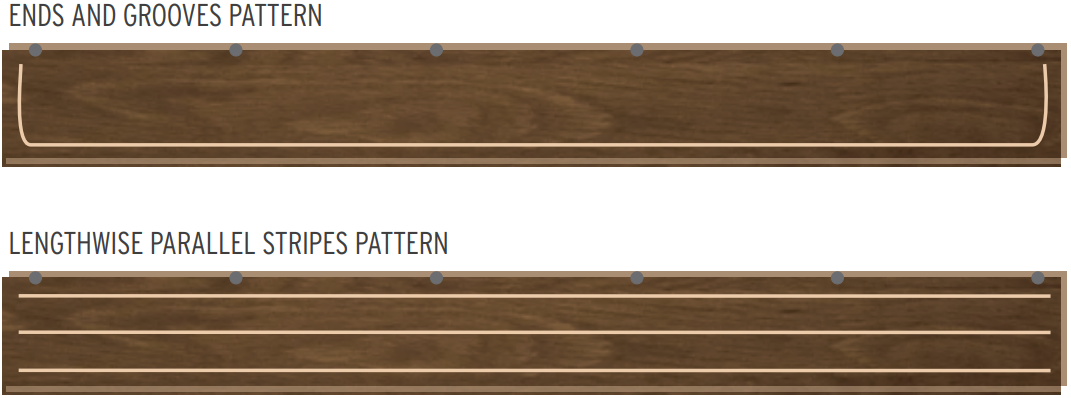

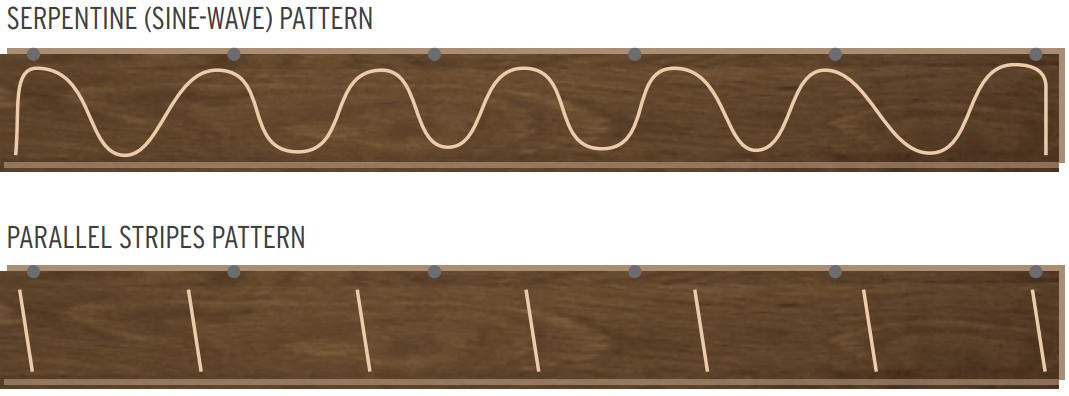

In addition to utilizing the correct fastener, you may also want to read one of our other episodes; Episode 1 – Adhesive Assist with Fastener to aid in the fastening of the wider engineered floors.

Additional information can be acquired from the manufacturer’s technical department of the products used on your floor. The National Wood Floor Association (NWFA) can be an additional resource. They can be reached at 800-422-4556 or online at www.woodfloors.org.

Quick links to the products mentioned in this episode…

Did you know Gehl Flooring Supply also provides underlayments for hardwood flooring installations? Check out our additional product offerings by clicking on the categorical menu bar at the top of this page.