Episode 9 – Environmental Conditions, Before, During and After the Installation

There are many factors that can play into the performance of a hardwood floor. None is more important than how moisture can affect flooring. Hardwood flooring professional know that wood is a natural material and can absorb and release moisture depending on the surrounding environmental conditions. Checking or possibly monitoring these conditions should start even before the wood is delivered to the jobsite.

If you have ever been to a NWFA Installation course, you would hear a decent amount of information and conversation regarding moisture and wood. How to test and document moisture on the jobsite and depending on conditions, when to install or not to install the flooring. As a matter of fact, the NWFA has a separate publication covering just this topic, “Moisture and Wood”, which can be an additional resource if you would like to understand more about how moisture can affect wood flooring.

For this article, we are going to cover controlling and maintaining the environmental conditions of the jobsite to minimize moisture related issues. As mentioned above, this starts BEFORE the flooring is delivered to the jobsite. For instance, your builder calls you and states ‘the job is ready for installation of the wood flooring’. In their mind, the schedule is conducive for the installation. A jobsite evaluation should be done at this time for any issues. While you may already be doing a pre delivery jobsite evaluation, here are a few items to make sure you are checking and verifying prior to the delivery of flooring:

- Is the jobsite complete to the required stage of construction?

- All roofing, flashing and gutters are complete

- All windows and doors are installed

- HVAC is up and running and set to maintain the manufacturer or NWFA installation guidelines

- Crawl space (if applicable) is properly encapsulated with no moisture present

- Has the exterior grading been done to allow for moisture to shed away from the building?

- While final landscaping may not be completely necessary, a completed rough grade will help minimize water pooling up against the building’s foundation and finding it’s way into the building.

- Has all ‘Wet Work’ been completed?

- All drywall and major painting have been competed

- The tile contractor has completed all installation and grouting

- After the above items have been checked, measure and document the moisture content of the subfloor or the concrete substrate in addition to taking the temperature/humidity of the jobsite.

- If your readings are too high, your flooring will absorb that moisture. Moisture content of the subfloor should be no more than 2-4% higher of the expected wood equilibrium moisture content or EMC (depending on width of flooring).

Here is a common phrase used in many installation courses regarding moisture…

“Get the jobsite ready for wood; then get the wood ready for the jobsite”.

What this means is do the above-mentioned checks and balances prior to scheduling the delivery of the wood. If the jobsite is not ready, your flooring will acclimate to these conditions and not the living conditions the flooring will be exposed to once the owner takes possession. This will cause an awkward conversation a few months down the road when that flooring does officially acclimate in place possibly causing cracking/popping, unsightly gaping and/or irreparable damage.

You have taken the time to check the jobsite conditions of your upcoming job prior to having the wood delivered. All exterior doors and windows have been installed and all ‘wet work’ has been completed. HVAC is up and running and the subfloor readings are within NWFA installation guidelines. Now you can have the flooring delivered and start installing the flooring, correct?

One more thing to do before the installation can begin, acclimation. The acclimation processes may vary depending on whether you are installing a prefinished or unfinished material. It can also vary depending on if it is solid or engineered. Check the installation guidelines of the material you are using to properly acclimate their flooring. Make sure the building owner is maintaining the living conditions DURING the acclimation. Take moisture readings using a moisture meter throughout the acclimation process. Document these numbers and the temperature and RH readings using a thermohydrometer. In any situation, there should be no more than a 4% difference between a wooden subfloor and the flooring. If the flooring is to be glued over a concrete slab, consult your adhesive manufacturer for their testing recommendations and guidelines.

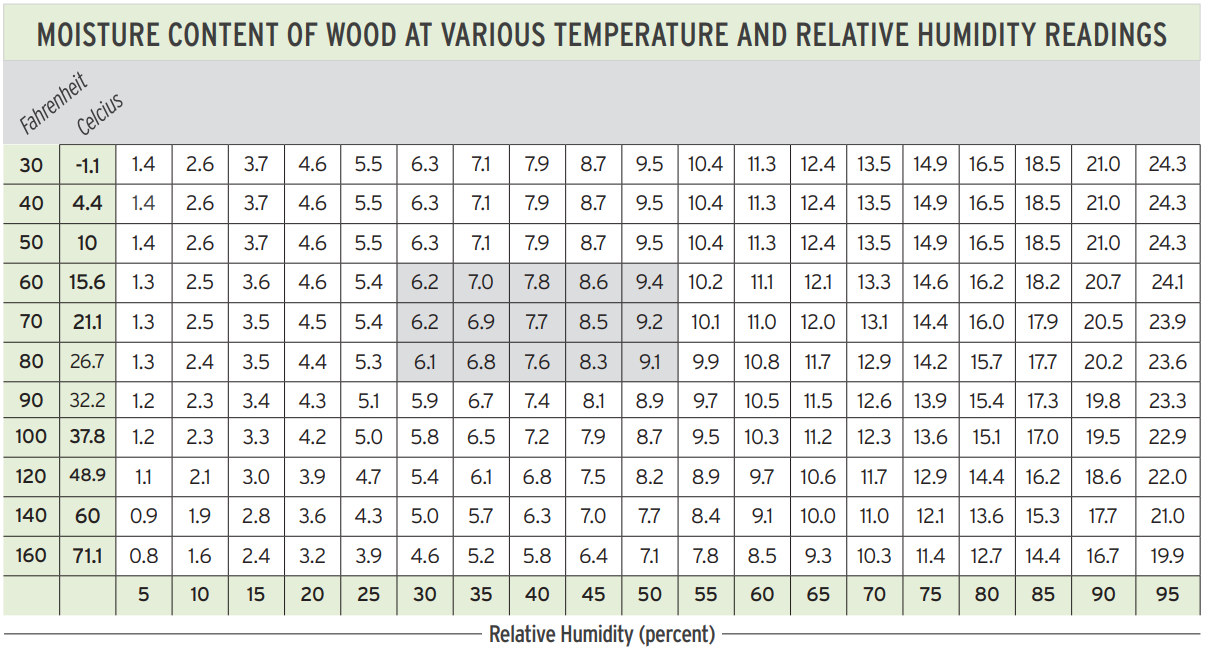

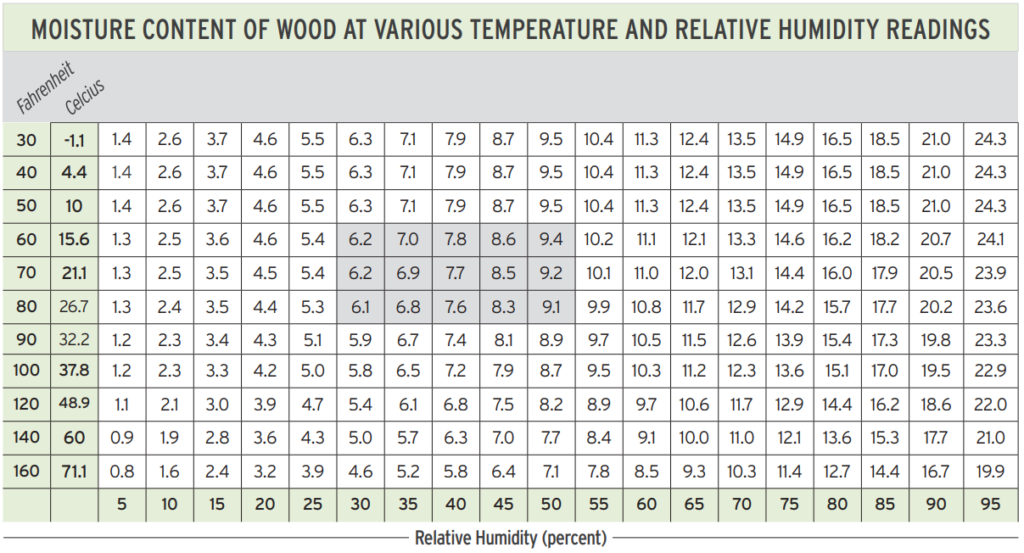

If you are not familiar with the acclimation process, dimensional stability and change coefficient of each wood species or figuring out the equilibrium moisture content of your area, the NWFA’s ‘Moisture and Wood” publication goes into great depth regarding these and many more items regarding moisture and wood. This moisture content graph below is commonly used while explaining the effects of moisture in wood.

This above graph is telling us that if we keep the temperature at 70 degrees and 40% RH, the EMC of that flooring, if kept in that environment, will eventually become 7.7%. If you are trying to install a floor that is going to be kept in these conditions, you will want to make sure you are getting multiple readings throughout the flooring to measure as close to 7.7% as possible before starting your installation. If you are not getting these readings, more time is needed for acclimation.

So now the flooring is at the correct EMC for the environment you are placing the flooring. Installation has been done and if it was unfinished, it has been sanded and finished. You have completed the job and are about to be paid for your work. This is the time that could be the most critical part of the long-term floor care. Advising your customer on how to best maintain their new floor AFTER the installation.

As explained in previous episodes and info bulletins; their new floor needs to be maintained at 60° and 80° and 30% to 50% relative humidity (or whatever is suggested by the flooring manufacturer). Along with the flooring manufacturers floor care guide, either one of these two bulletins can be left behind with the floor owner to explain their role in the long-term performance of their new flooring…

Info Bulletin #20 – Did You Know_Episode 6 – Long Term Hardwood Floor Care

Info Bulletin #60 – Did You Know_Episode 2 – Seasonal Gaps and Moisture Control

Understanding the relationship between moisture and wood allows us to better understand what to expect as we work with the flooring products and how they will perform in the environment we are planning on placing them. It is an undisputed fact that moisture (or lack of moisture), whether in the form of liquid, vapor, or bound water, will affect the performance of wood flooring, regardless of style, species, width, installation method, or construction. As professionals in this industry, it is our responsibility to mitigate the adverse effects of moisture on wood floors and to communicate to our customers how to properly maintain them.

Additional information can be acquired from the manufacturer’s technical department of the products used on your floor. The National Wood Floor Association (NWFA) can be an additional resource. They can be reached at 800-422-4556 or online at www.woodfloors.org.

Quick links to products related to this episode…